Home » Case study » Pump Selection for an Irrigation Project

Pump Selection for an Irrigation Project

I have an irrigation system with 350 LPS capacity at 7 bar. It is a TSE(treated sewage effluent) irrigation for a landascpae project in Middle east.

I need to get the information about the pump selection.

Which type of pump can I select? (Horizontal, vertical centrifugal, vertical turbine pumps)?

Any idea about the selction of the number of Duty pumps and Stand by pumps).

Whats the maximum operating hours can provided to the selected pump based on 24 hours interval.

In order to do a proper selection we need the following information;

- Set up of the reservoir - in other words, will pumps have positive suction and how much.

Also needed to be sure you get the right product is the general quality of the treated effluent - PH and max solid sizes.

I have to assume the duty point you mentioned is at pump discharge; if not and it should be at irrigation point then please also provide:

- Lay-out of the irrigation system (distances and diameters + material selected for the pipes in order to calculate pressure losses)

Furthermore it seems wise to engineer your system on 3 different duty points:

1- Minimum flow

2- Average flow

3- Max flow

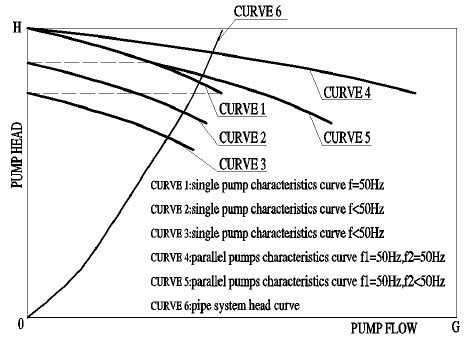

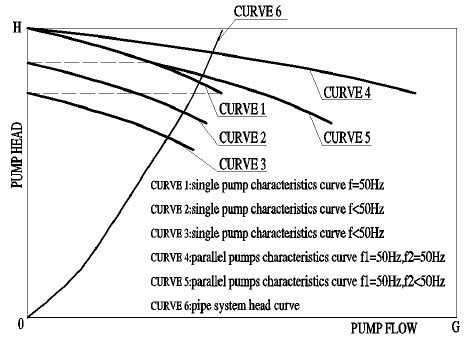

This way you can break-down the selection and select pumps based on maximum efficiency in all 3 conditions. Obviously it seems sensible to use multiple pump systems and or a variable frequency drive - VFD driven system. For safety reasons we would always advise at least 2 pumps for such a system.

The type of pump to be selected cannot be properly be decided without the above info - it is however common to use surface pumps such as double suctions.

First determine the minimum flow rate required for tech Project. Then divide the system capacity of 350 LPS with the minimum flow rate required. This will give you the number of pumps you should use in the Project (you can add one or two more pumps as stand by). If one Pump is installed having Flow Rate of 350 LPS @ 7 bar then a very large motor rating shall be required. Which will require a large power consumption if the operation of pump is intermittent.

Secondly determine what type of pump you have and does the pump control by variable frequency drive? Since it is TSE hence it cannot be underground water. It may be an underground tank or surface tank. In any case determine what is the depth of the tank. If the tank depth is less than or equal to 6 meters than install horizontal self-priming centrifugal pumps with open impeller (since it is treated sewage water most likely with suspended solids).

However, if the depth of tank is more than 6 meters then install deep well turbine pumps or Vertical Non-Clogging Pumps.

Since you have also asked for well sizing design. You will have to determine the incoming rate of treated sewage that is to be stored in the pump well. From the outflow rate of 350 LPS you will have to determine how much storage time you require in tech pump well.

Since the Project is located in the Middle East where the day temperatures are very high so it is advisable to operate the pump during dusk and dawn. During this time the temperatures will fall and evaporation rates will be comparatively less.

I need to get the information about the pump selection.

Which type of pump can I select? (Horizontal, vertical centrifugal, vertical turbine pumps)?

Any idea about the selction of the number of Duty pumps and Stand by pumps).

Whats the maximum operating hours can provided to the selected pump based on 24 hours interval.

In order to do a proper selection we need the following information;

- Set up of the reservoir - in other words, will pumps have positive suction and how much.

Also needed to be sure you get the right product is the general quality of the treated effluent - PH and max solid sizes.

I have to assume the duty point you mentioned is at pump discharge; if not and it should be at irrigation point then please also provide:

- Lay-out of the irrigation system (distances and diameters + material selected for the pipes in order to calculate pressure losses)

Furthermore it seems wise to engineer your system on 3 different duty points:

1- Minimum flow

2- Average flow

3- Max flow

This way you can break-down the selection and select pumps based on maximum efficiency in all 3 conditions. Obviously it seems sensible to use multiple pump systems and or a variable frequency drive - VFD driven system. For safety reasons we would always advise at least 2 pumps for such a system.

The type of pump to be selected cannot be properly be decided without the above info - it is however common to use surface pumps such as double suctions.

First determine the minimum flow rate required for tech Project. Then divide the system capacity of 350 LPS with the minimum flow rate required. This will give you the number of pumps you should use in the Project (you can add one or two more pumps as stand by). If one Pump is installed having Flow Rate of 350 LPS @ 7 bar then a very large motor rating shall be required. Which will require a large power consumption if the operation of pump is intermittent.

Secondly determine what type of pump you have and does the pump control by variable frequency drive? Since it is TSE hence it cannot be underground water. It may be an underground tank or surface tank. In any case determine what is the depth of the tank. If the tank depth is less than or equal to 6 meters than install horizontal self-priming centrifugal pumps with open impeller (since it is treated sewage water most likely with suspended solids).

However, if the depth of tank is more than 6 meters then install deep well turbine pumps or Vertical Non-Clogging Pumps.

Since you have also asked for well sizing design. You will have to determine the incoming rate of treated sewage that is to be stored in the pump well. From the outflow rate of 350 LPS you will have to determine how much storage time you require in tech pump well.

Since the Project is located in the Middle East where the day temperatures are very high so it is advisable to operate the pump during dusk and dawn. During this time the temperatures will fall and evaporation rates will be comparatively less.

Post a Comment:

You may also like:

Featured Articles

Variable frequency drive energy ...

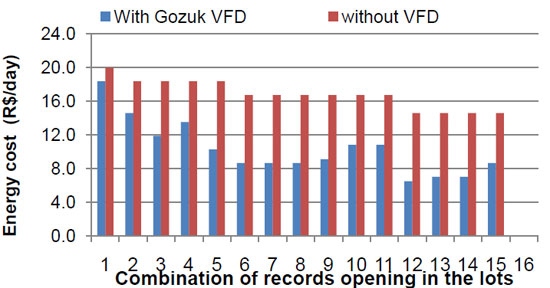

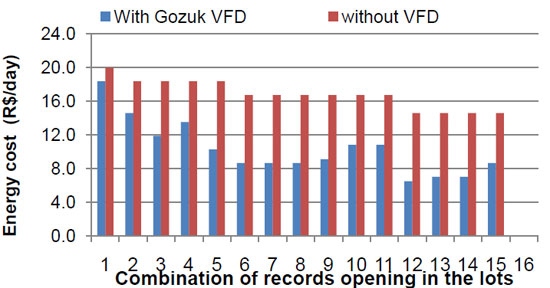

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...Variable frequency drive on Cooling ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...VFD in China plantation irrigation ...

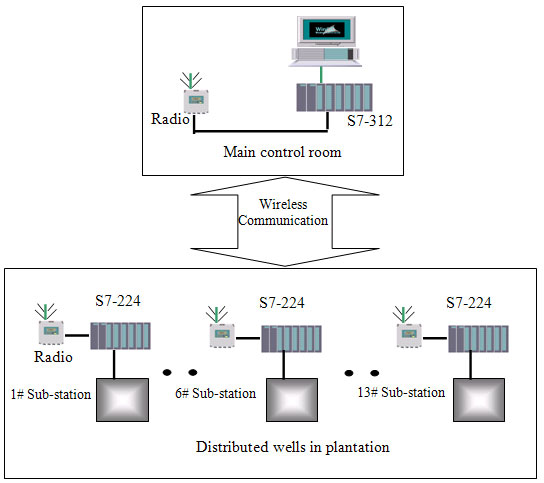

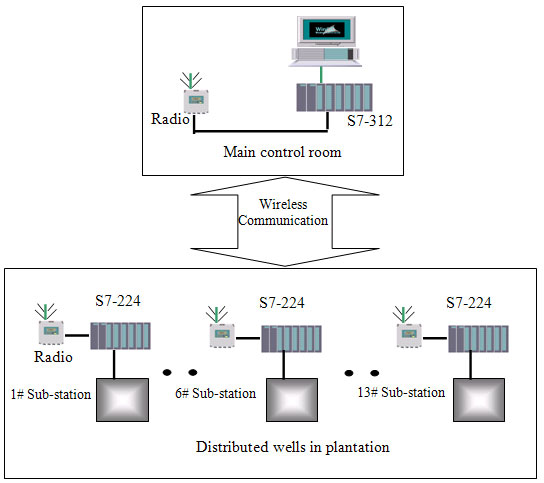

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...VFD for pumps in variable flow water ...

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

VFD manufacturers