Variable Frequency Drive mounting location

The variable frequency drive chassis is intended to be mounted in a switchboard style enclosure with the heatsink section protruding through the rear wall of the enclosure. The input and output line reactors provided as part of the variable frequency drive should be mounted within the switchboard adjacent to, or on the enclosure floor, below the variable frequency drive chassis.

The control console is separate to the VFD chassis and intended to be mounted on the front of the switchboard enclosure for convenient operation.

Mechanical protection may be required to prevent damage to the heatsink section in some environments. The variable frequency drive is deigned for use in a pollution degree 21 environment. The system integrator and user are responsible for providing and maintaining this environment inside the switchboard enclosure for the lifetime of the equipment.

VFD installation considerations

Confined spaces are generally defined in Occupational Health and Safety (OH&S) regulations to mean spaces where special precautions are necessary to ensure a safe breathing atmosphere, or there is limited access for escape/rescue in case of emergency.

The control console is separate to the VFD chassis and intended to be mounted on the front of the switchboard enclosure for convenient operation.

Mechanical protection may be required to prevent damage to the heatsink section in some environments. The variable frequency drive is deigned for use in a pollution degree 21 environment. The system integrator and user are responsible for providing and maintaining this environment inside the switchboard enclosure for the lifetime of the equipment.

VFD installation considerations

- The variable frequency drive must be mounted on a vibration free vertical surface, away from heat radiating sources. Do not mount the variable frequency drive in direct sunlight or on a hot surface.

- The variable frequency drive must be mounted vertically. No other mounting orientation is acceptable.

- If the VFD is mounted inside another enclosure, the total heat dissipation and resulting temperature rise in the enclosure must be allowed for.

- Attention is drawn to the potential for condensation in vulnerable environments. Additional precautions may be required for all enclosure types.

- The installation location and environment should provide for safe access and working conditions for service personnel. Do not mount the variable frequency drive in "confined spaces"

- Do not drill holes in the enclosure except in the gland plate.

- Remove the gland plate before drilling cable holes.

- Do not allow metal shavings or any other conductive material to enter the enclosure or damage may result.

Confined spaces are generally defined in Occupational Health and Safety (OH&S) regulations to mean spaces where special precautions are necessary to ensure a safe breathing atmosphere, or there is limited access for escape/rescue in case of emergency.

Post a Comment:

You may also like:

Featured Articles

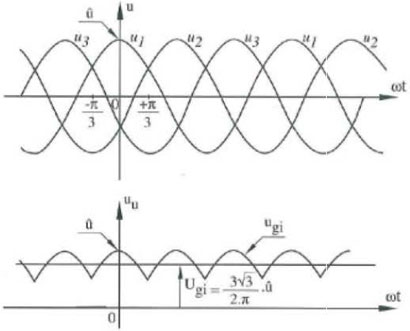

Variable frequency drive Rectifier

To understand variable frequency drive (VFD) better, it's necessary to explain some of the main parts of the variable frequency ...

To understand variable frequency drive (VFD) better, it's necessary to explain some of the main parts of the variable frequency ...

To understand variable frequency drive (VFD) better, it's necessary to explain some of the main parts of the variable frequency ...

To understand variable frequency drive (VFD) better, it's necessary to explain some of the main parts of the variable frequency ...What is VFD, How it works? - VFD ...

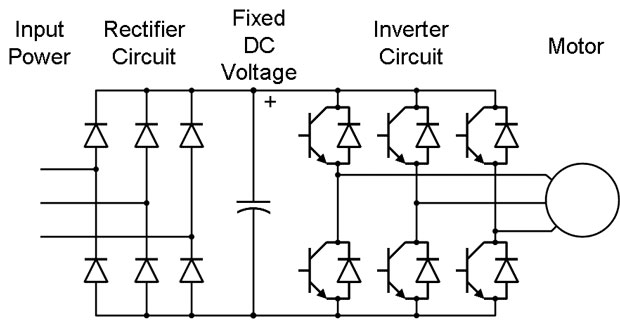

VFD is shorted for Variable Frequency Drive (also known as AC Drives and Inverters) -- that's used to make an AC motor working in ...

VFD is shorted for Variable Frequency Drive (also known as AC Drives and Inverters) -- that's used to make an AC motor working in ...

VFD is shorted for Variable Frequency Drive (also known as AC Drives and Inverters) -- that's used to make an AC motor working in ...

VFD is shorted for Variable Frequency Drive (also known as AC Drives and Inverters) -- that's used to make an AC motor working in ...VFD: Insulated Gate Bipolar Transistor ...

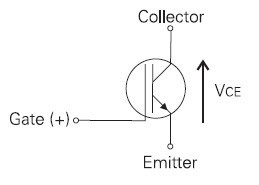

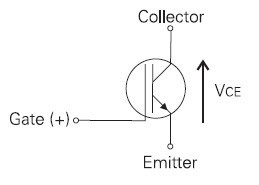

IGBT (insulated gate bipolar transistor) provides a high switching speed necessary for PWM VFD operation. IGBTs are capable of ...

IGBT (insulated gate bipolar transistor) provides a high switching speed necessary for PWM VFD operation. IGBTs are capable of ...

IGBT (insulated gate bipolar transistor) provides a high switching speed necessary for PWM VFD operation. IGBTs are capable of ...

IGBT (insulated gate bipolar transistor) provides a high switching speed necessary for PWM VFD operation. IGBTs are capable of ...VFD controlled Induction motor ...

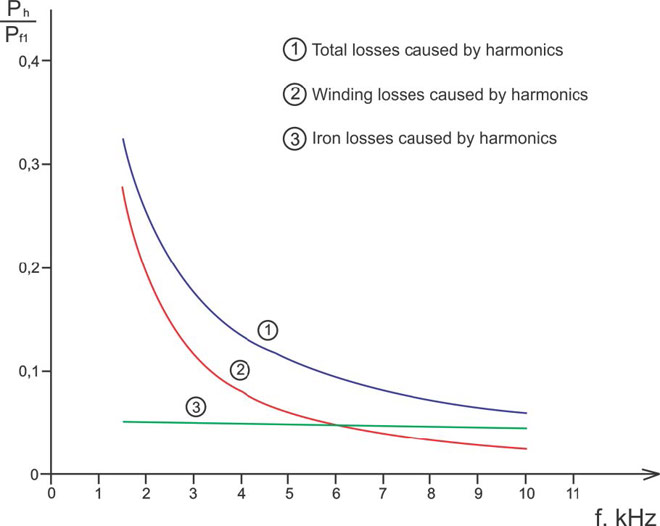

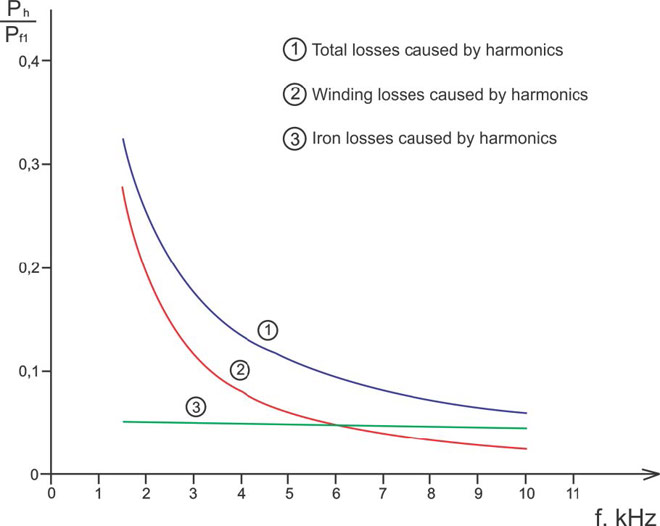

This paper presents a procedure to measure the efficiency on an induction motor fed by a VFD by the all operation range to speed ...

This paper presents a procedure to measure the efficiency on an induction motor fed by a VFD by the all operation range to speed ...

This paper presents a procedure to measure the efficiency on an induction motor fed by a VFD by the all operation range to speed ...

This paper presents a procedure to measure the efficiency on an induction motor fed by a VFD by the all operation range to speed ...Three phase inverters

In the variable frequency drive rectifier paper, it explains how to go from three phase alternating current voltage to a direct ...

In the variable frequency drive rectifier paper, it explains how to go from three phase alternating current voltage to a direct ...

In the variable frequency drive rectifier paper, it explains how to go from three phase alternating current voltage to a direct ...

In the variable frequency drive rectifier paper, it explains how to go from three phase alternating current voltage to a direct ...

VFD manufacturers