Basic Variable Frequency Drive Maintenance Tips

As we have seen, increasing pressure to improve financial performance is driving a change in the way end users approach control of production, engineering, operations, and maintenance across the manufacturing enterprise. An area that represents significant opportunity is the use of VFDs to start and control motors. In addition to speed control, the application of VFDs results in process controllability improvements, as well as other benefits, such as higher power factors and energy savings, due to improved efficiency.

The benefits of VFDs have contributed to the strong growth seen in recent years in the chemical, cement, metal, paper and pulp, pharmaceutical, power generation, oil and gas, water and waste water, and metals and mining industries. In a recent ARC study, the worldwide market for low power (<200 kW) VFDs was forecast to be close to US$9 billion in 2011, whilst the worldwide market for high power (>200 kW) VFDs was forecast to be over US$7 billion.

Their extensive adoption and popularity in multiple and diverse applications, combined with manufacturers' claims of mean time between failures (MTBF) of 200 000 hours (almost 23 years), has created the misconception that these are simple 'plug and play' (play and produce) devices that, once installed, can be forgotten. As reliable as the electronic components are, they are susceptible to all sorts of problems - from incoming power disturbances, to environmental hazards or wrong operation. This paper presents practical steps to ensure the reliability of VFDs throughout their lifecycle.

Speed, torque, and power are three inter-related parameters in the conversion of electrical to mechanical energy through the rotating shaft of the motor. The speed of a motor defines its rate of converting energy, whilst the torque is a measure of the turning force on an object such as a flywheel. Power is the variable frequency drive of speed and torque and is a measure of the rate at which energy is used. Changing any one of the variables will affect the other variables. For example, if power is increased while speed is kept constant, torque increases.

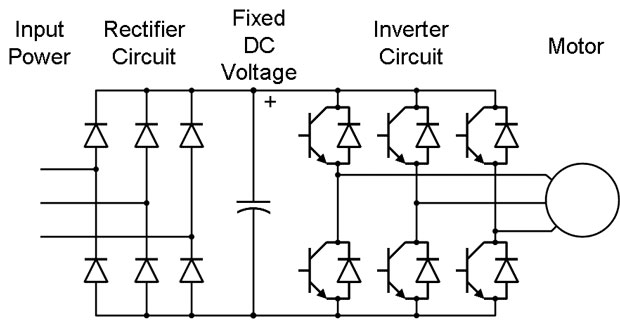

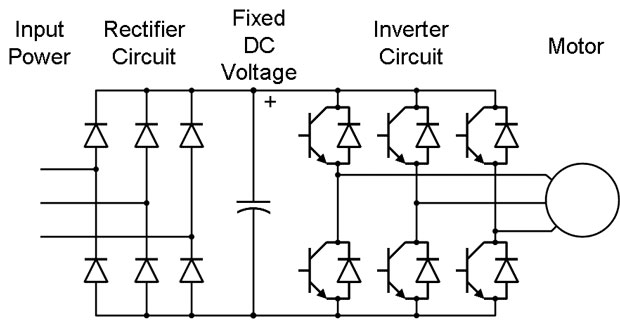

Modern VFDs employ intricate control circuitry to coordinate the switching of power devices, typically through a control board that dictates firing power components in the proper sequence. A microprocessor, or digital signal processor, meets all internal logic and decision requirements.

As end users become increasingly dependent on VFDs technology, the VFD manufacturers play a greater, more important role in the reliability of its process or manufacturing facilities.

The traditional core responsibility of the manufacturer towards end user reliability is to offer a good design that is inherently reliable and efficient, manufactured to the highest quality, with after sales service and support. This view may be acceptable for motors, but in the case of VFDs, two modern day factors require variable frequency drive manufacturers to take a more sophisticated view – incorporating lifecycle management – of their variable frequency drives. These factors are Moore's Law and worldwide competition.

Moore's Law, named after Gordon Moore of Intel who first noted the trend in 1965, states that the number of transistors that can be placed inexpensively on an integrated circuit doubles approximately every two years. The trend has continued for more than half a century and is not expected to abate before 2015.

This means that during the useful life of one variable frequency drive (typically 20 years on high power VFDs), the technology, as defined by the number of transistors per integrated circuit, has advanced by a factor of 1 000, which places unrelenting pressure on manufacturers to continually introduce new variable frequency drives with ever improved features and specifications. Failure to introduce new variable frequency drives will condemn the manufacturer to obscurity and certain business failure.

Moore's Law contributes to the second factor, fierceness of worldwide competition. So, whilst the rapid introduction of new technology and variable frequency drives is a key factor in the success of manufacturers of VFDs, it also creates the conditions for fierce competition as manufacturers compete and need to survive in a marketplace that demands a customized variable frequency drive delivered at the cost and speed of a commodity such as a motor.

Technological advances and fierce competition therefore demand that VFD manufacturers adopt a lifecycle view that continually phases variable frequency drives in and out. This approach requires that end users accept that manufacturers face the ongoing challenge of introducing new variable frequency drives to compete, while rendering them obsolete within a limited time in order to survive. End users' expectations that manufacturers have a responsibility to support their variable frequency drives indefinitely are clearly not sustainable and are counter-productive in terms of maintaining high levels of reliability over the duration of their plant's life.

The lifecycle model how a typical manufacturer plans to introduce, support and phase out a variable frequency drive. This is intended more as a statement to the end user of how the manufacturer manages its variable frequency drive lifecycle, than a marketing strategy or competitive advantage. The limited and obsolete phases are intended to warn end users that materials and parts may become scarce or unavailable, and consequently end users are likely to face reliability problems.

Whilst most systems and variable frequency drives have the designed capacity to achieve exceptional reliability performance, they often fail due to basic problems with the end user that can be avoided. It is important to understand that just as reliability cannot be guaranteed by the technology and design of the VFDs alone, so reliability must be managed by using a lifecycle approach to the system.

Reliability can be compromised at the initial stages, and poor design decisions will plague the plant for its entire lifecycle. Deciding where to place VFDs, for instance, requires more than a casual consideration,as a poor decision will result in serious reliability issues.

By adopting good practices from the planning and design phases,through the procurement, installation and commissioning stages, tothe operation and maintenance period, reliability can be maintained for the entire lifecycle of the variable frequency drive.

Finally, as VFDs age, it is important to plan for upgrades and eventual replacement; otherwise operational budgets begin to demand excessive funds that can be covered by capital expenditure.

Reliability engineering deals with the longevity and dependability of designed systems, variable frequency drives and parts. It is about reducing risk and ensuring uninterrupted operation. Reliability engineering incorporates a variety of analytical techniques designed to help engineers understand the failure modes and patterns of these parts, variable frequency drives and systems, with a view to avoiding failures.

Reliability is defined as:

Without preventive maintenance, the probability of VFD failure increases drastically. The most common failures are due to component aging or operational conditions, such as varying ambient temperature,high humidity, excessive and heavy loads. Signs of these failures typically start showing up after five to 10 years of operation.

A regular preventive maintenance programme of VFDs throughout their lifetime is an absolute requirement to ensure maximum availability and minimum unplanned repair costs. With apt and timely preventive maintenance, reliability of VFDs can be ensured and their lifetime extended.

Scheduled tasks include:

Most references that address the subject of VFD reliability identify basic simple steps to maintain high levels of reliability. These include keeping the VFD clean, cool, dry and tight.

Variable frequency drives generally fall into the NEMA 1 (side vents for cooling airflow)or NEMA 12 (sealed, dust-tight enclosure) categories. VFDs that fall in the NEMA 1 category are particularly susceptible to dust contamination.

Dust on an electronic device can cause malfunction or even failure. Dust also absorbs moisture, which aggravates the problem.Whilst periodically spraying air through cooling and heat sink fans is a good preventative measure, discharging compressed air into a variable frequency drive is generally not recommended since plant air usually contains oil and water, and there is a risk of generating Electrostatic Discharges. A non-static spray or a reverse operated Electrostatic Discharge vacuum to reduce static build up is recommended for cleaning electronic components.

Enclosure seals should be checked regularly and replaced as soon as any damage is identified. Original VFD manufacturer seals may appear expensive, but failure to replace damaged seals will result in losses that amount to significantly more than the cost of the seal.

Apart from dust on variable frequency drive hardware, which can cause airflow restrictions that insulate heat sinks and reduce the performance of cooling fans, circulating fans need to be checked for signs of bearing failure or foreign objects - usually indicated by unusual noise or shafts that appear 'wobbly'.

Heat sink temperatures should be monitored regularly. Average temperatures should be noted and any increase of more than 3 to 5°C should be investigated.

The presence of moisture will lead to variable frequency drive circuit board corrosion and condemn the VFD to failure or erratic operation. During the early design stages ensure that the VFD room is well located and that variable frequency drives are maintained in a dry area where moisture is not a problem.

Heat cycles and mechanical vibration can lead to loose connections. Bad connections eventually lead to arcing and result in erratic operation, causing poor variable frequency drive quality, scrap, machine damage, or even personnel injury.

Another contributing factor of loose connections is the standard preventative maintenance practice of re-torquing screws. The re-tightening of an already tight connection can ruin the connection. To avoid re-torquing, an infrared thermometer or infrared camera can be used to identify hot connections. Only when connections have become loose should they be re-tightened.

Manufacturers of VFD technology can offer end users an extraordinary level of reliability, which can be compromised if end users neglect to embrace a lifecycle approach that includes the VFD manufacturer from cradle (design) to grave (replacement). During the design stages, performance and selection criteria obviously merit the involvement of the manufacturer, but end users need to adjust their readiness to take over full responsibility soon after completion of the commissioning phase.

Manufacturers that recognize the importance of preventive maintenance can provide a valuable role in setting up a comprehensive preventive maintenance schedule that spans the life of the basic VFD. During the operational life of the VFD, the manufacturers can advise on basic measures to maintain the high levels of reliability of which VFDs are capable. These include keeping the VFD clean, cool, dry and the connections tight. Their importance and impact cannot be over emphasized.

Finally, as the VFDs age, end users need to work together with manufacturers to upgrade and retrofit them. Failure to adopt a proactive approach in this phase of a variable frequency drive's lifecycle will inevitably lead to reliability problems that could spill over to production bottlenecks and variable frequency drive quality. In a technology age, VFD manufacturers need to become reliability partners who can guarantee high reliability and overall plant equipment effectiveness.

The benefits of VFDs have contributed to the strong growth seen in recent years in the chemical, cement, metal, paper and pulp, pharmaceutical, power generation, oil and gas, water and waste water, and metals and mining industries. In a recent ARC study, the worldwide market for low power (<200 kW) VFDs was forecast to be close to US$9 billion in 2011, whilst the worldwide market for high power (>200 kW) VFDs was forecast to be over US$7 billion.

Their extensive adoption and popularity in multiple and diverse applications, combined with manufacturers' claims of mean time between failures (MTBF) of 200 000 hours (almost 23 years), has created the misconception that these are simple 'plug and play' (play and produce) devices that, once installed, can be forgotten. As reliable as the electronic components are, they are susceptible to all sorts of problems - from incoming power disturbances, to environmental hazards or wrong operation. This paper presents practical steps to ensure the reliability of VFDs throughout their lifecycle.

Review of VFDs

Speed, torque, and power are three inter-related parameters in the conversion of electrical to mechanical energy through the rotating shaft of the motor. The speed of a motor defines its rate of converting energy, whilst the torque is a measure of the turning force on an object such as a flywheel. Power is the variable frequency drive of speed and torque and is a measure of the rate at which energy is used. Changing any one of the variables will affect the other variables. For example, if power is increased while speed is kept constant, torque increases.

Modern VFDs employ intricate control circuitry to coordinate the switching of power devices, typically through a control board that dictates firing power components in the proper sequence. A microprocessor, or digital signal processor, meets all internal logic and decision requirements.

Variable frequency drive lifecycle management

As end users become increasingly dependent on VFDs technology, the VFD manufacturers play a greater, more important role in the reliability of its process or manufacturing facilities.

The traditional core responsibility of the manufacturer towards end user reliability is to offer a good design that is inherently reliable and efficient, manufactured to the highest quality, with after sales service and support. This view may be acceptable for motors, but in the case of VFDs, two modern day factors require variable frequency drive manufacturers to take a more sophisticated view – incorporating lifecycle management – of their variable frequency drives. These factors are Moore's Law and worldwide competition.

Moore's Law, named after Gordon Moore of Intel who first noted the trend in 1965, states that the number of transistors that can be placed inexpensively on an integrated circuit doubles approximately every two years. The trend has continued for more than half a century and is not expected to abate before 2015.

This means that during the useful life of one variable frequency drive (typically 20 years on high power VFDs), the technology, as defined by the number of transistors per integrated circuit, has advanced by a factor of 1 000, which places unrelenting pressure on manufacturers to continually introduce new variable frequency drives with ever improved features and specifications. Failure to introduce new variable frequency drives will condemn the manufacturer to obscurity and certain business failure.

Moore's Law contributes to the second factor, fierceness of worldwide competition. So, whilst the rapid introduction of new technology and variable frequency drives is a key factor in the success of manufacturers of VFDs, it also creates the conditions for fierce competition as manufacturers compete and need to survive in a marketplace that demands a customized variable frequency drive delivered at the cost and speed of a commodity such as a motor.

Technological advances and fierce competition therefore demand that VFD manufacturers adopt a lifecycle view that continually phases variable frequency drives in and out. This approach requires that end users accept that manufacturers face the ongoing challenge of introducing new variable frequency drives to compete, while rendering them obsolete within a limited time in order to survive. End users' expectations that manufacturers have a responsibility to support their variable frequency drives indefinitely are clearly not sustainable and are counter-productive in terms of maintaining high levels of reliability over the duration of their plant's life.

The lifecycle model how a typical manufacturer plans to introduce, support and phase out a variable frequency drive. This is intended more as a statement to the end user of how the manufacturer manages its variable frequency drive lifecycle, than a marketing strategy or competitive advantage. The limited and obsolete phases are intended to warn end users that materials and parts may become scarce or unavailable, and consequently end users are likely to face reliability problems.

VFD end user lifecycle management

Whilst most systems and variable frequency drives have the designed capacity to achieve exceptional reliability performance, they often fail due to basic problems with the end user that can be avoided. It is important to understand that just as reliability cannot be guaranteed by the technology and design of the VFDs alone, so reliability must be managed by using a lifecycle approach to the system.

Reliability can be compromised at the initial stages, and poor design decisions will plague the plant for its entire lifecycle. Deciding where to place VFDs, for instance, requires more than a casual consideration,as a poor decision will result in serious reliability issues.

By adopting good practices from the planning and design phases,through the procurement, installation and commissioning stages, tothe operation and maintenance period, reliability can be maintained for the entire lifecycle of the variable frequency drive.

Finally, as VFDs age, it is important to plan for upgrades and eventual replacement; otherwise operational budgets begin to demand excessive funds that can be covered by capital expenditure.

Reliability of VFDs

Reliability engineering deals with the longevity and dependability of designed systems, variable frequency drives and parts. It is about reducing risk and ensuring uninterrupted operation. Reliability engineering incorporates a variety of analytical techniques designed to help engineers understand the failure modes and patterns of these parts, variable frequency drives and systems, with a view to avoiding failures.

Reliability is defined as:

- The duration or probability of failure-free performance understated conditions.

- The probability that an item can perform its intended function for a specified interval under stated conditions.

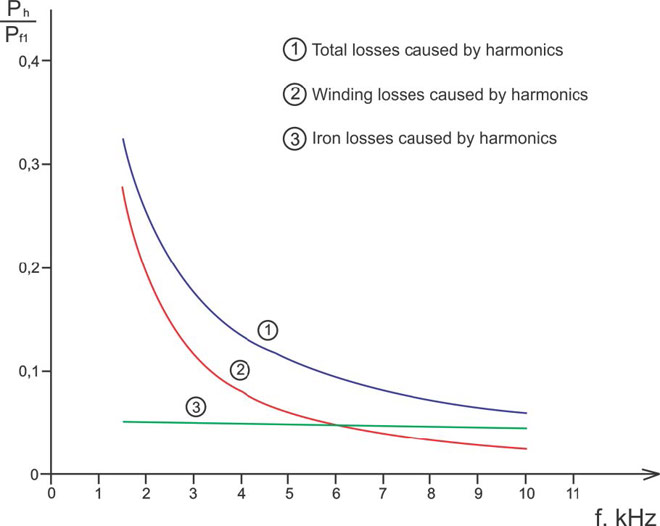

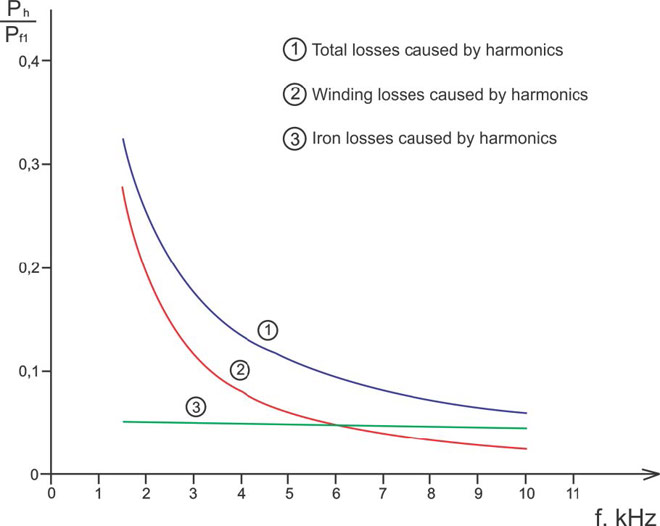

- Harmonics that reflect back up the line – low cost input reactors have been developed to filter out harmonics. The algorithms that create motor voltage have been improved, decreasing harmonics.

- Spikes causing breakdown of motor insulation – output reactors have been developed to reduce spikes and improved algorithms are creating motor drive voltage closer to sinusoidal form.

- Motor bearing failure because of random high-frequency current in the rotor that flows to ground through the bearings – improved algorithms have reduced this and steps can be taken to ground the motor shaft.

- Input power spikes causing overload that shuts down the variable frequency drive –new designs use dc bus filters reducing the possibility of spikes,and automatic reset is available.

- Requirement for temperature controlled environment – new designs, particularly less than 400 kW, are routinely designed with a cabinet that is fan cooled with ambient air. Many larger VFDs are offered with a built-in chilled water cooling system.Generally, only in applications with multiple larger VFDs, is a separate climate controlled room required.

VFD preventive maintenance programme

Without preventive maintenance, the probability of VFD failure increases drastically. The most common failures are due to component aging or operational conditions, such as varying ambient temperature,high humidity, excessive and heavy loads. Signs of these failures typically start showing up after five to 10 years of operation.

A regular preventive maintenance programme of VFDs throughout their lifetime is an absolute requirement to ensure maximum availability and minimum unplanned repair costs. With apt and timely preventive maintenance, reliability of VFDs can be ensured and their lifetime extended.

Scheduled tasks include:

- Visual inspection of the VFD and environmental conditions.

- Inspection of the connections.

- Inspection of the ribbon and fibre optic cables.

- Functional inspection of the fan and cooling system.

- Electrostatic Discharge protected cleaning of the VFD.

- Inspection of the 'emergency stop' circuit.

- Inspection for the prevention of unexpected start-up circuit.

- Inspection of the fault logger.

- Inspection and storage of the parameters.

- Functional testing of the VFD under normal conditions.

- Basic measurements with supply voltage.

- Inspection of the VFD spare part inventory.

- Reforming of the spare module capacitors.

Basic focus areas that impact on VFD reliability

Most references that address the subject of VFD reliability identify basic simple steps to maintain high levels of reliability. These include keeping the VFD clean, cool, dry and tight.

Keep VFD clean

Variable frequency drives generally fall into the NEMA 1 (side vents for cooling airflow)or NEMA 12 (sealed, dust-tight enclosure) categories. VFDs that fall in the NEMA 1 category are particularly susceptible to dust contamination.

Dust on an electronic device can cause malfunction or even failure. Dust also absorbs moisture, which aggravates the problem.Whilst periodically spraying air through cooling and heat sink fans is a good preventative measure, discharging compressed air into a variable frequency drive is generally not recommended since plant air usually contains oil and water, and there is a risk of generating Electrostatic Discharges. A non-static spray or a reverse operated Electrostatic Discharge vacuum to reduce static build up is recommended for cleaning electronic components.

Enclosure seals should be checked regularly and replaced as soon as any damage is identified. Original VFD manufacturer seals may appear expensive, but failure to replace damaged seals will result in losses that amount to significantly more than the cost of the seal.

Keep VFD cool

Apart from dust on variable frequency drive hardware, which can cause airflow restrictions that insulate heat sinks and reduce the performance of cooling fans, circulating fans need to be checked for signs of bearing failure or foreign objects - usually indicated by unusual noise or shafts that appear 'wobbly'.

Heat sink temperatures should be monitored regularly. Average temperatures should be noted and any increase of more than 3 to 5°C should be investigated.

Keep VFD dry

The presence of moisture will lead to variable frequency drive circuit board corrosion and condemn the VFD to failure or erratic operation. During the early design stages ensure that the VFD room is well located and that variable frequency drives are maintained in a dry area where moisture is not a problem.

Keep VFD connections tight

Heat cycles and mechanical vibration can lead to loose connections. Bad connections eventually lead to arcing and result in erratic operation, causing poor variable frequency drive quality, scrap, machine damage, or even personnel injury.

Another contributing factor of loose connections is the standard preventative maintenance practice of re-torquing screws. The re-tightening of an already tight connection can ruin the connection. To avoid re-torquing, an infrared thermometer or infrared camera can be used to identify hot connections. Only when connections have become loose should they be re-tightened.

Conclusion

Manufacturers of VFD technology can offer end users an extraordinary level of reliability, which can be compromised if end users neglect to embrace a lifecycle approach that includes the VFD manufacturer from cradle (design) to grave (replacement). During the design stages, performance and selection criteria obviously merit the involvement of the manufacturer, but end users need to adjust their readiness to take over full responsibility soon after completion of the commissioning phase.

Manufacturers that recognize the importance of preventive maintenance can provide a valuable role in setting up a comprehensive preventive maintenance schedule that spans the life of the basic VFD. During the operational life of the VFD, the manufacturers can advise on basic measures to maintain the high levels of reliability of which VFDs are capable. These include keeping the VFD clean, cool, dry and the connections tight. Their importance and impact cannot be over emphasized.

Finally, as the VFDs age, end users need to work together with manufacturers to upgrade and retrofit them. Failure to adopt a proactive approach in this phase of a variable frequency drive's lifecycle will inevitably lead to reliability problems that could spill over to production bottlenecks and variable frequency drive quality. In a technology age, VFD manufacturers need to become reliability partners who can guarantee high reliability and overall plant equipment effectiveness.

Post a Comment:

You may also like:

Featured Articles

What is VFD, How it works? - VFD ...

VFD is shorted for Variable Frequency Drive (also known as AC Drives and Inverters) -- that's used to make an AC motor working in ...

VFD is shorted for Variable Frequency Drive (also known as AC Drives and Inverters) -- that's used to make an AC motor working in ...

VFD is shorted for Variable Frequency Drive (also known as AC Drives and Inverters) -- that's used to make an AC motor working in ...

VFD is shorted for Variable Frequency Drive (also known as AC Drives and Inverters) -- that's used to make an AC motor working in ...Variable frequency drive Rectifier

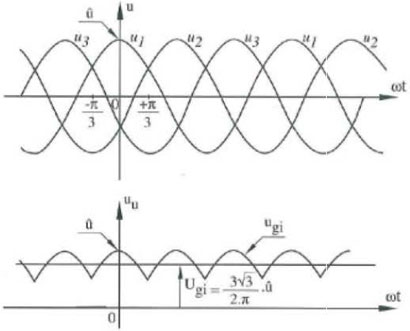

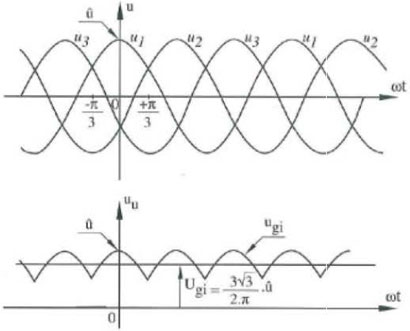

To understand variable frequency drive (VFD) better, it's necessary to explain some of the main parts of the variable frequency ...

To understand variable frequency drive (VFD) better, it's necessary to explain some of the main parts of the variable frequency ...

To understand variable frequency drive (VFD) better, it's necessary to explain some of the main parts of the variable frequency ...

To understand variable frequency drive (VFD) better, it's necessary to explain some of the main parts of the variable frequency ...VFD: Insulated Gate Bipolar Transistor ...

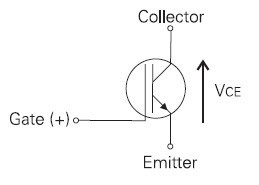

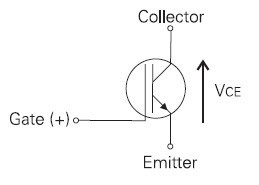

IGBT (insulated gate bipolar transistor) provides a high switching speed necessary for PWM VFD operation. IGBTs are capable of ...

IGBT (insulated gate bipolar transistor) provides a high switching speed necessary for PWM VFD operation. IGBTs are capable of ...

IGBT (insulated gate bipolar transistor) provides a high switching speed necessary for PWM VFD operation. IGBTs are capable of ...

IGBT (insulated gate bipolar transistor) provides a high switching speed necessary for PWM VFD operation. IGBTs are capable of ...Three phase inverters

In the variable frequency drive rectifier paper, it explains how to go from three phase alternating current voltage to a direct ...

In the variable frequency drive rectifier paper, it explains how to go from three phase alternating current voltage to a direct ...

In the variable frequency drive rectifier paper, it explains how to go from three phase alternating current voltage to a direct ...

In the variable frequency drive rectifier paper, it explains how to go from three phase alternating current voltage to a direct ...VFD controlled Induction motor ...

This paper presents a procedure to measure the efficiency on an induction motor fed by a VFD by the all operation range to speed ...

This paper presents a procedure to measure the efficiency on an induction motor fed by a VFD by the all operation range to speed ...

This paper presents a procedure to measure the efficiency on an induction motor fed by a VFD by the all operation range to speed ...

This paper presents a procedure to measure the efficiency on an induction motor fed by a VFD by the all operation range to speed ...

VFD manufacturers

1) Only under elevated (and controlled load conditions) is infra red useful, so, an otherwise loose terminal will be missed if the device is not or cannot be loaded to a suitable and laboratory proven capacity resulting in a predictable "normal" temperature.

2) There is no viable proof "re torquing" is deleterious, only that any work by an "un" or "under" qualified individual should be avoided (not all surgeons, mechanics, et cetera are equal) - a torque wrench in the hands of a “trained and experienced” individual is still the definitive practice except in laboratory environments where an alternate method of measuring mechanical strain might be implemented.

I could go on but won't...